Background

This blog explores the transformative role of Artificial Intelligence (AI) and the Internet of Things (IoT) in predictive maintenance within the manufacturing sector. It outlines how these technologies are enabling manufacturers to move beyond traditional reactive and preventative maintenance strategies towards a more proactive and efficient approach, reducing downtime, optimizing asset utilization, and ultimately improving overall operational efficiency. We will delve into the key components of a predictive maintenance system, the benefits it offers, and the challenges associated with its implementation.

Introduction

Manufacturing industries are constantly seeking ways to improve efficiency, reduce costs, and minimize downtime. Traditional maintenance strategies, such as reactive (run-to-failure) and preventative (time-based) maintenance, often fall short in addressing these needs. Reactive maintenance is costly due to unexpected breakdowns and production stoppages. Preventative maintenance, while more proactive, can lead to unnecessary maintenance tasks and the replacement of components that still have useful life.

Predictive maintenance (PdM) offers a more sophisticated approach by leveraging data analysis and machine learning to predict equipment failures before they occur. This allows maintenance teams to schedule repairs and replacements proactively, minimizing downtime and optimizing asset utilization. The integration of AI and IoT technologies is crucial for enabling effective predictive maintenance programs.

The Role of IoT in Predictive Maintenance

The Internet of Things (IoT) provides the foundation for collecting real-time data from manufacturing equipment. IoT sensors can be deployed to monitor various parameters, including:

- Temperature: Overheating can indicate potential issues with motors, bearings, or other components.

- Vibration: Excessive vibration can signal imbalances, misalignments, or wear and tear.

- Pressure: Monitoring pressure levels in hydraulic systems or pipelines can detect leaks or blockages.

- Acoustic Emissions: Unusual noises can indicate developing problems in rotating machinery.

- Oil Analysis: Monitoring the condition of lubricating oil can reveal wear particles and contamination.

- Electrical Current: Changes in current draw can indicate motor inefficiencies or developing faults.

These sensors transmit data wirelessly to a central platform for analysis. The volume and velocity of data generated by IoT devices are often referred to as “Big Data,” which requires advanced analytical techniques to extract meaningful insights.

The Role of AI in Predictive Maintenance

Artificial Intelligence (AI), particularly machine learning (ML), plays a critical role in analyzing the data collected by IoT sensors and predicting equipment failures. ML algorithms can be trained on historical data, including past failures, operating conditions, and maintenance records, to identify patterns and anomalies that indicate potential problems.

Key AI techniques used in predictive maintenance include:

- Supervised Learning: Algorithms are trained on labeled data (e.g., data labeled as “failure” or “normal”) to predict future failures. Common supervised learning algorithms include regression models, decision trees, and support vector machines.

- Unsupervised Learning: Algorithms identify patterns and anomalies in unlabeled data. This is useful for detecting unexpected behavior that may indicate a developing problem. Clustering and anomaly detection algorithms are commonly used.

- Reinforcement Learning: Algorithms learn to optimize maintenance schedules based on feedback from the environment. This can be used to dynamically adjust maintenance intervals based on real-time conditions.

- Deep Learning: Neural networks with multiple layers can learn complex patterns from large datasets. Deep learning is particularly effective for analyzing sensor data and identifying subtle anomalies that may be missed by other techniques.

AI algorithms can provide valuable insights, such as:

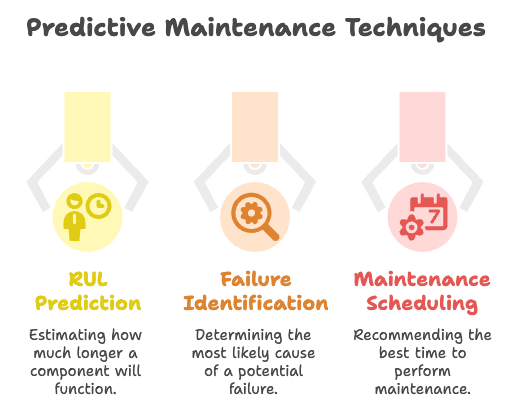

- Remaining Useful Life (RUL) Prediction: Estimating how much longer a component or machine is likely to function before failure.

- Failure Mode Identification: Determining the most likely cause of a potential failure.

- Optimal Maintenance Scheduling: Recommending the best time to perform maintenance to minimize downtime and costs.

Benefits of Predictive Maintenance

Implementing a predictive maintenance program offers numerous benefits to manufacturing organizations:

- Reduced Downtime: By predicting failures before they occur, maintenance teams can schedule repairs proactively, minimizing unplanned downtime and production losses.

- Optimized Asset Utilization: Predictive maintenance helps extend the lifespan of equipment by identifying and addressing potential problems early on.

- Lower Maintenance Costs: By performing maintenance only when necessary, predictive maintenance reduces unnecessary maintenance tasks and the replacement of components that still have useful life.

- Improved Safety: By identifying potential safety hazards before they lead to accidents, predictive maintenance helps create a safer working environment.

- Increased Production Efficiency: By minimizing downtime and optimizing asset utilization, predictive maintenance helps increase overall production efficiency.

- Better Inventory Management: Predictive maintenance allows for more accurate forecasting of spare parts needs, reducing inventory costs and ensuring that parts are available when needed.

Challenges of Implementing Predictive Maintenance

While the benefits of predictive maintenance are significant, implementing a successful program can be challenging:

- Data Quality: The accuracy of predictive maintenance models depends on the quality of the data used to train them. Poor data quality can lead to inaccurate predictions and ineffective maintenance decisions.

- Data Integration: Integrating data from various sources, such as IoT sensors, maintenance records, and operating logs, can be complex and time-consuming.

- Algorithm Selection: Choosing the right AI algorithms for a specific application can be challenging. Different algorithms have different strengths and weaknesses, and the best choice depends on the specific data and goals.

- Expertise: Implementing and maintaining a predictive maintenance program requires expertise in data science, machine learning, and manufacturing processes.

- Cost: Implementing a predictive maintenance program can be expensive, requiring investments in IoT sensors, data analytics platforms, and skilled personnel.

- Organizational Change: Implementing predictive maintenance requires a shift in mindset from reactive to proactive maintenance. This can require significant organizational change and training.

- Security: Protecting the data collected by IoT sensors from cyberattacks is crucial. Security measures must be implemented to prevent unauthorized access and data breaches.

Conclusion

Predictive maintenance, powered by AI and IoT, is revolutionizing the manufacturing industry. By leveraging real-time data and advanced analytics, manufacturers can predict equipment failures, optimize maintenance schedules, and improve overall operational efficiency. While implementing a predictive maintenance program can be challenging, the benefits in terms of reduced downtime, lower costs, and improved safety make it a worthwhile investment for many manufacturing organizations. As AI and IoT technologies continue to evolve, predictive maintenance will become even more sophisticated and accessible, further transforming the manufacturing landscape.